High Voltage System Safety: Best Practices on Industrial Job Sites

High-voltage electrical systems are essential to modern industrial facilities, but they also introduce serious risks when not managed correctly. From manufacturing plants to processing facilities and large commercial campuses, working around high-voltage power requires more than technical skill. It demands careful planning, clear procedures, and a strong safety culture that protects everyone on site.

At Stewart Electric Company, Inc., safety has always been a priority. Decades of experience working in complex electrical environments have reinforced the importance of disciplined practices and attention to detail. Below are key best practices that help keep industrial job sites safe while maintaining reliable electrical operations.

Identifying High-Voltage Risks Before Work Begins

Every safe project starts with understanding the hazards involved. High-voltage systems can create dangers such as electrical shock, arc flash incidents, equipment damage, and unexpected power release. These risks are often heightened in industrial settings where large motors, transformers, and switchgear are involved.

Before work begins, teams should conduct a thorough site evaluation. This includes identifying voltage levels, available fault current, system layout, and environmental conditions. Understanding these factors allows crews to choose the right safety measures and avoid preventable incidents.

Lockout and Tagout as a Critical Safety Step

Lockout and tagout procedures are one of the most effective ways to protect workers on industrial job sites. Before any electrical work is performed, all energy sources must be isolated and clearly identified. This process ensures that equipment cannot be energized while work is underway.

Successful lockout and tagout programs rely on consistency and accountability. Each worker involved should understand their role and verify that systems are fully de-energized before starting work. Clear documentation and communication help prevent mistakes that could lead to serious injuries.

Wearing the Right Protective Equipment

Personal protective equipment plays a vital role in reducing the impact of electrical hazards. In high-voltage environments, PPE must be carefully selected based on the specific risks present.

Arc-rated clothing, voltage-rated gloves, face protection, safety glasses, and insulated tools are commonly required. PPE must be properly maintained and inspected before use. Worn or damaged equipment can compromise safety and should be replaced immediately. Just as important, workers must be trained on how to use protective gear correctly to ensure it provides the intended level of protection.

Maintaining Safe Distances Around Energized Equipment

High-voltage equipment requires strict control of working distances. Minimum approach distances help protect workers from accidental contact and electrical arcing. These distances should be clearly marked and reinforced using physical barriers, signage, or insulated coverings.

Limiting access to high-voltage areas is especially important on busy industrial sites. Only authorized and trained personnel should be allowed near energized systems. This reduces the risk of accidental exposure and helps maintain a safer work environment.

Keeping Electrical Equipment in Reliable Condition

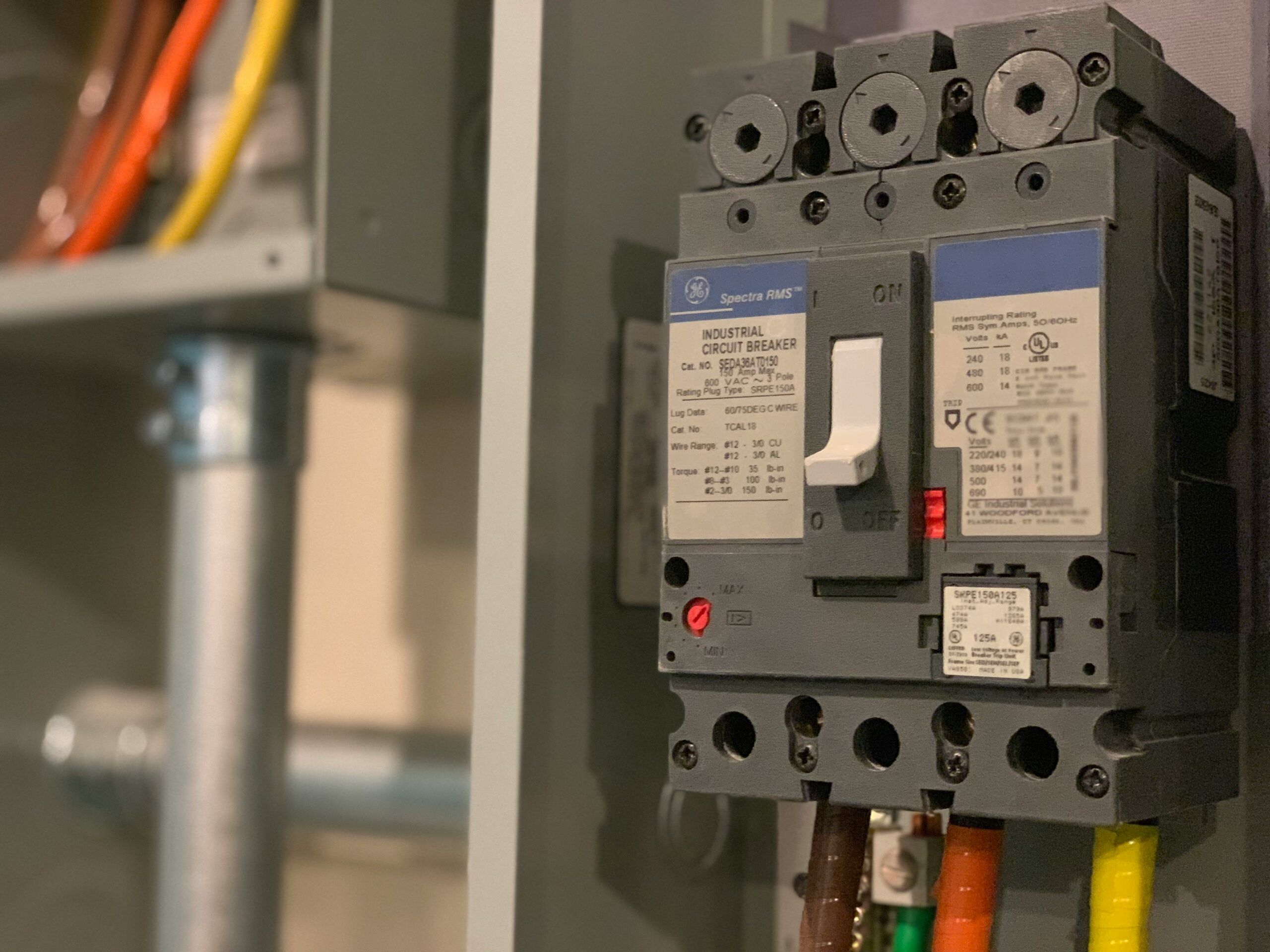

Well-maintained electrical equipment is a key component of job site safety. Switchgear, transformers, cables, and protective devices should be inspected regularly for signs of wear, overheating, corrosion, or loose connections.

Routine maintenance programs such as infrared inspections, testing, and preventative repairs can identify potential problems early. Addressing issues before they escalate helps prevent unexpected failures that can put workers at risk and disrupt operations.

Training and Communication on Industrial Sites

Even the best safety equipment cannot replace proper training. Workers involved in high-voltage electrical tasks should receive ongoing education on safety procedures, system operation, and emergency response.

Clear communication is equally important. Job briefings allow teams to review potential hazards, confirm safety steps, and coordinate responsibilities. Encouraging open dialogue helps ensure that concerns are addressed quickly and that everyone understands the plan before work begins.

Managing Environmental and Site Conditions

Industrial environments often present additional challenges that affect electrical safety. Moisture, dust, vibration, and temperature extremes can all impact equipment performance and worker protection.

Using properly rated enclosures, sealing components, and selecting materials designed for harsh conditions helps reduce risk. Temporary power setups should also be carefully planned and inspected to meet the same safety standards as permanent installations.

A Longstanding Commitment to Safety

Since 1976, Stewart Electric Company, Inc. has earned the trust of commercial and industrial clients by delivering safe, reliable electrical solutions. High-voltage work requires a careful balance of technical expertise and strict safety practices.

By prioritizing hazard identification, proper procedures, protective equipment, and ongoing training, industrial job sites can operate more safely and efficiently. When safety is treated as a fundamental part of every project, everyone benefits.

If your facility needs an experienced commercial and industrial electrical contractor that puts safety first, Stewart Electric Company, Inc. is ready to support your next project. Reach out to our team at 256.536.4375 to learn how we can help keep your operations running safely and reliably.