Lighting Layout Mistakes That Reduce Workplace Productivity

Most people think of lighting as a basic building feature. Flip the switch and the lights come on. But in commercial and industrial environments, lighting design has a direct effect on how efficiently people work. When lighting layouts are planned poorly, employees experience fatigue, frustration, and slower performance without always realizing lighting is the cause.

In busy facilities across North Alabama, every minute of productivity matters. Whether the space is a manufacturing floor, warehouse, office, or government building, lighting must support the tasks being performed. When it does not, output declines and errors increase. Understanding where lighting layouts go wrong is the first step toward improving workplace performance.

Treating Every Space the Same

A common lighting mistake is assuming that one lighting layout works for an entire facility. Different areas have different visual demands. A packaging station needs focused illumination. A hallway needs general visibility. An office requires balanced light for screens and paperwork. When all these spaces share the same lighting approach, some areas end up too bright while others feel dim.

This imbalance forces workers to adjust constantly. They may strain to see details or feel uncomfortable under harsh brightness. Both situations slow work and cause unnecessary stress. A thoughtful lighting plan adapts to each workspace instead of applying a single solution everywhere.

Creating Shadows Where Work Happens

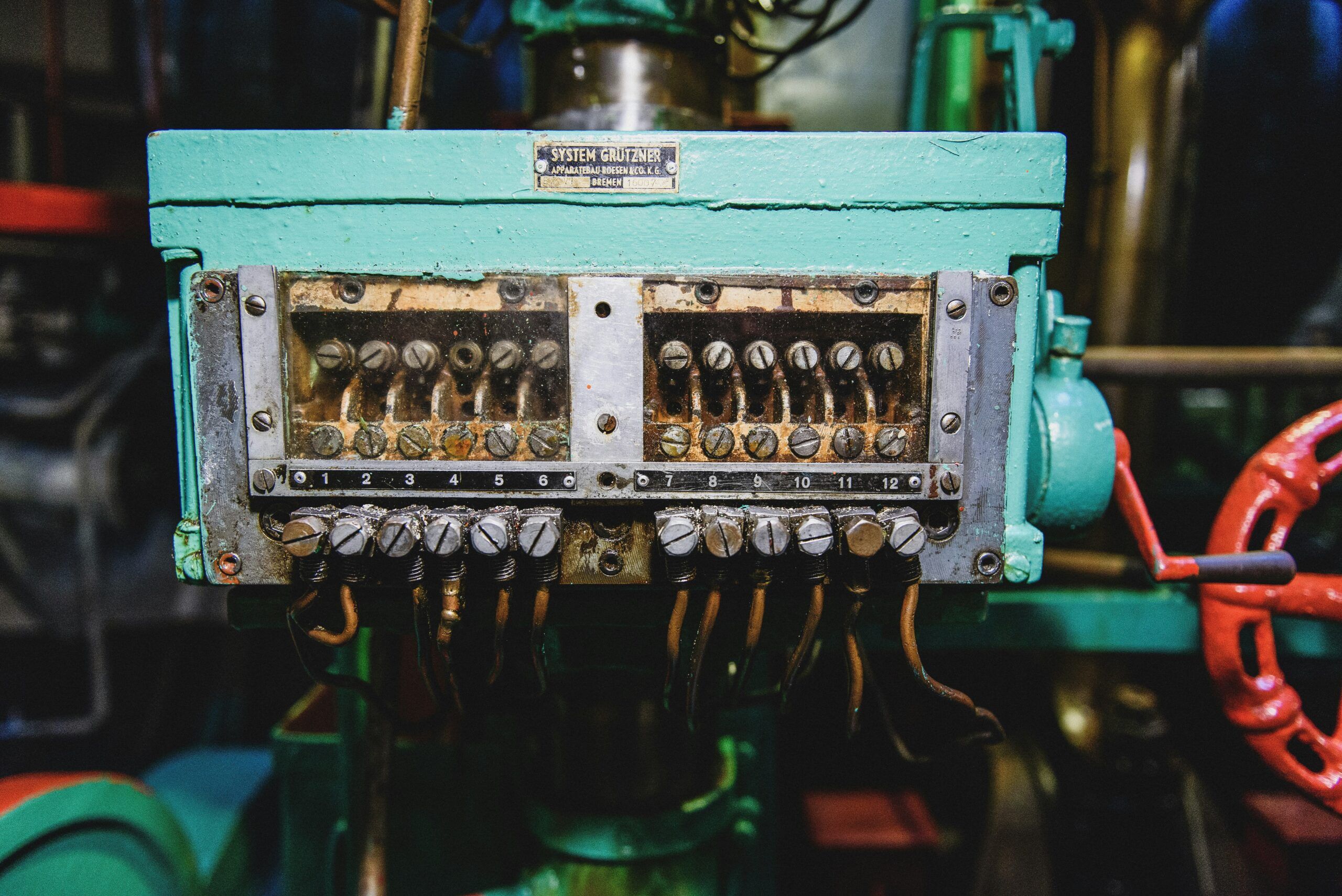

Lighting fixtures that are placed without considering workstation positioning often create shadows in the very areas where people need to see clearly. This is common in industrial settings where equipment placement changes over time, but lighting layouts remain unchanged.

Shadows make tasks take longer and increase the chance of mistakes. Workers may lean or shift positions to compensate, which leads to discomfort and distraction. Proper fixture placement prevents this by ensuring even illumination across work surfaces and machinery.

Producing Glare That Distracts Workers

Glare is another productivity drain that often goes unnoticed. Lights that are too bright or angled incorrectly can shine directly into a worker’s eyes or reflect off glossy surfaces. This causes discomfort and visual fatigue throughout the day.

When employees are constantly adjusting their posture or squinting to reduce glare, concentration drops. A professional lighting layout avoids glare by selecting proper fixture angles, diffusers, and mounting heights that keep light where it is needed.

Using Light Levels That Are Too Low

Many older facilities still operate under lighting standards that no longer match modern work demands. Detailed assembly tasks, digital interfaces, inspection stations, and inventory systems all require stronger and more precise lighting than in the past.

If illumination levels are too low, workers slow down to compensate. They may rely on handheld lights or take extra time to confirm what they see. Increasing light levels through an updated layout improves accuracy and reduces eye strain.

Overlooking Light Color and Clarity

Lighting is not only about brightness. Color temperature and color rendering affect how clearly people see objects and read information. Outdated lighting that produces dull or yellow toned light can make spaces feel tired and reduce visual clarity.

Modern LED lighting provides crisp clean light that helps workers stay alert and improves recognition of colors and markings. When lighting layouts ignore light quality, facilities miss an easy opportunity to boost focus and comfort.

Forgetting How Daylight Changes Space

Buildings with windows and skylights benefit from natural light but only when artificial lighting is designed to work alongside it. Without proper planning, daylight creates bright zones and dim zones that shift throughout the day.

This inconsistency distracts workers and causes glare on screens and reflective surfaces. Integrating daylight into lighting design creates steady illumination from morning to evening which keeps a workspace comfortable.

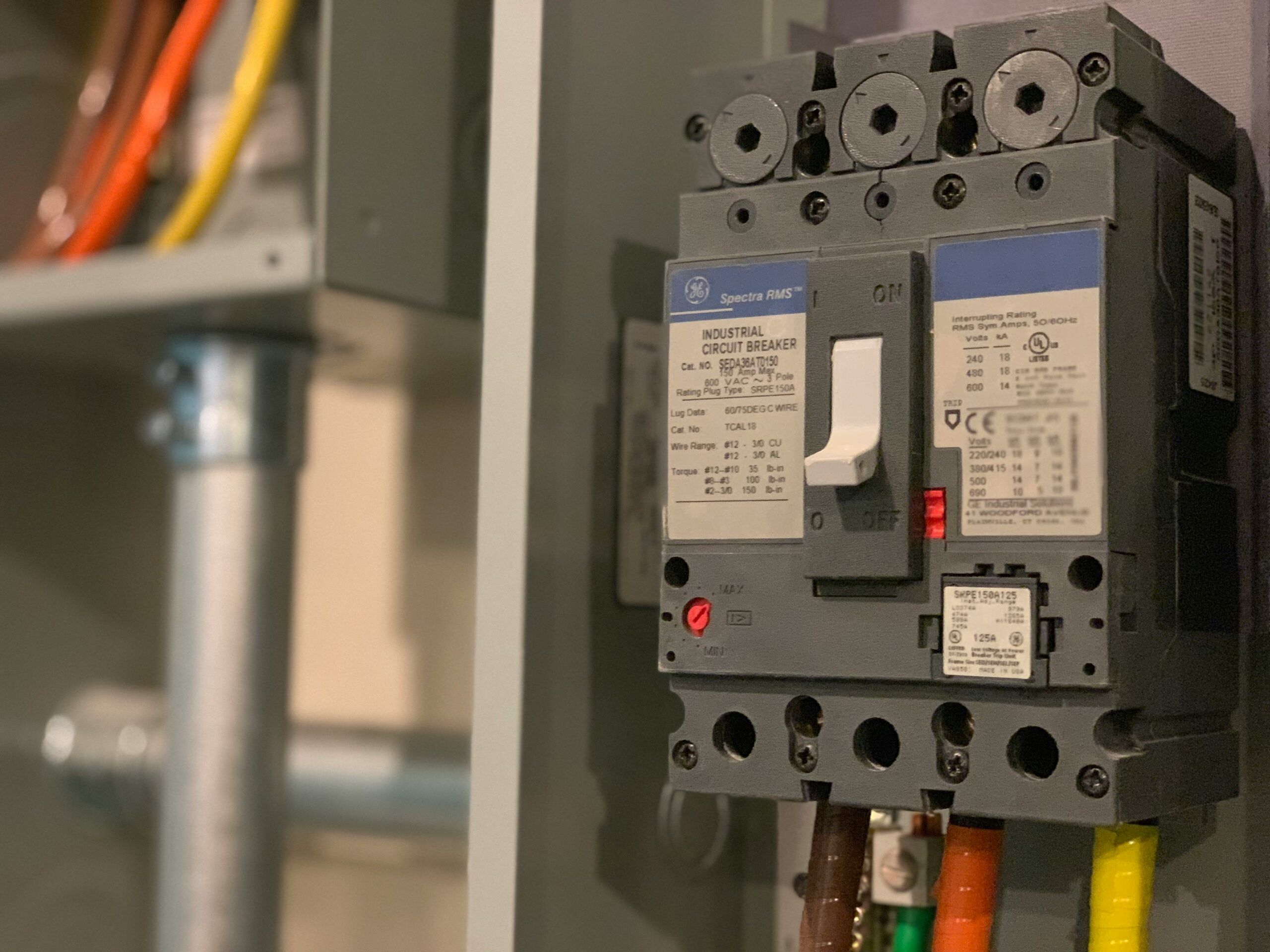

Skipping Lighting Controls

Another frequent oversight is installing lighting that cannot adapt to how the space is used. Areas may stay fully lit even when empty while occupied zones lack flexibility for different tasks or shifts.

Lighting controls allow facilities to adjust brightness based on occupancy and time of day. When lighting responds to real use patterns, energy costs drop, and employees benefit from consistent lighting conditions.

Letting Maintenance Fall Behind

Even the best lighting layout loses effectiveness if fixtures are dirty, aging, or burned out. Uneven lighting slowly develops, and workers adapt without realizing visibility has declined.

A good lighting plan includes maintenance strategy from the start. Long life fixtures, accessible installation, and regular inspection keep lighting performance steady over time.

Better Lighting Leads to Better Performance

Fixing lighting layout mistakes is not simply replacing bulbs. It involves understanding how people move, where tasks occur, and what visual conditions are required for safe and efficient work. When lighting supports employees instead of working against them, productivity rises naturally.

Stewart Electric Company, Inc. provides professional commercial and industrial lighting design for facilities across North Alabama and Southern Middle Tennessee. From warehouse layouts to office upgrades and specialty industrial lighting, the right plan makes every workspace more effective.

When lighting is designed with purpose, people work better without even thinking about the lights above them. Contact Stewart Electric Company, Inc. at 256.536.4375 today or visit us online for more information!